PRODUCT

-

Gears, Splined Shafts, Toothed Joints - Worm-screw gear units- Helical worm-gears

- Splined Shafts and Couplings

- Hirth Couplings

- Racks

-

Cams with complex profiles and/or controlled acceleration

-

Membrane self-centering systems

-

Special gearboxes and mechanized heads

-

Expansion and Locking Clamps

- Special Fifth Wheels

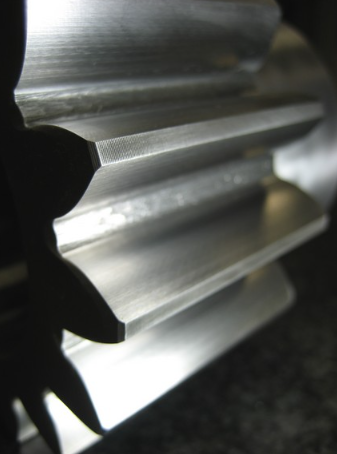

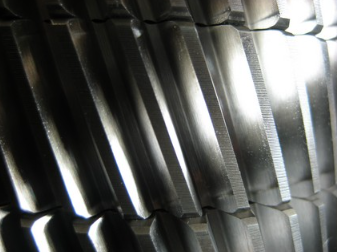

Gears, Splined Shafts, Toothed Joints

The company was born as a manufacturer of special gears and the experience accrued throughout sixty years – together with consistent technological development- has made of Moretti Srl a reference point in all those cases where you need effective optimization of the gears and/or special manufacturing requirements.

Dedicated tools for special gears and materials of difficult processing (e.g. titanium, stainless steel such as17-4-PH H1000) are internally designed.

Moretti Srl can develop involute gears of straight or helical external teeth, cut and ground with the greatest accuracy in compliance with DIN 3960 – 3962 Class 4 with standard module from 0.5 to 14, chain teeth, internal gears – also ground wherever feasible – straight tooth tapered gears, Gleason spiral-shaped teeth with running in and c/l detection or ground and toothed joints ground when required.

All the above with the sole limitation of dimensions, which must be between 6 and 750 mm as related to the diameter and up to 2000 mm as related to length.

Special in-house developed manufacturing processes allow Moretti srl developing sprocket wheels and shafts with teeth of very significant modules (up to Mn 80), which would be difficult to be developed through conventional process methods. The only limitation is the dimensions, which must be Max. Ø. 1000 mm L. 350 for the wheels and max. Ø 450mm L. 800 for the shafts.